Ремонт трансформаторів

Розробка конструкторської та технологічної документації, технічне керівництво і виконання фахівцями НІЦ робіт з профілактичного і відновлювального ремонту, а також комплексу заходів з метою подовження терміну служби трансформатора.

Докладніше

Діагностика трансформаторів

Оцінка справності обладнання, визначення виду, причини і небезпеки дефекту.

Докладніше

Монтаж трансформаторів

Технічне керівництво монтажем і введенням в експлуатацію трансформаторного обладнання всіх класів напруги.

Докладніше

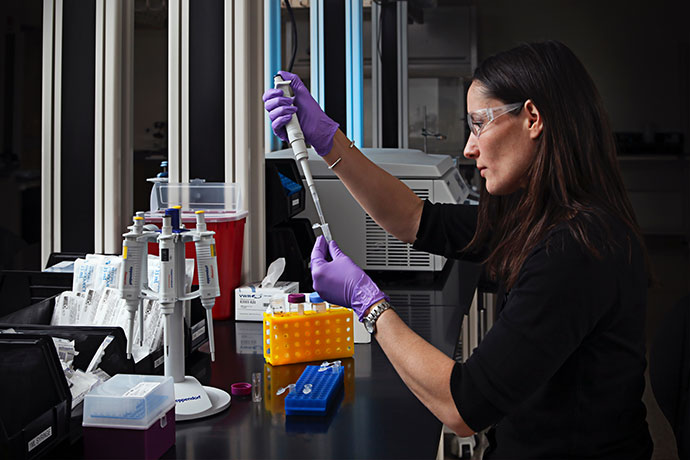

Випробування трансформаторного масла

Виконавши випробування проби трансформаторного масла в нашій лабораторії, ми відповідаємо на головні питання про стан трансформатора.

ДокладнішеПодовження терміну служби трансформатора.

Майже 25% силових трансформаторів, встановлених в країнах СНД, досягли нормованого терміну експлуатації - 25 років або наближаються до нього.

Для поновлення та подовження терміну служби трансформатора НІЦ "ЗТЗ-Сервіс" виконує

- Обстеження технічного стану трансформатора, оцінку фізичного та морального зносу конструкції

- Відновлення механічного стану трансформатора

- Відновлення запасу електричної міцності шляхом сушіння, очищення, спеціальної регенерації, а також реконструкції

- Зниження швидкості подальшого старіння за допомогою герметизації, поліпшення охолодження, забезпечення довговічності масла

- Впровадження ефективного захисту від пошкодження, попередження вибуху і пожежі

- Комплекс попередніх, проміжних і випробувань з функціональною перевіркою обладнання

- Повний технічний супровід подальшої експлуатації трансформатора

Розробка

НІЦ "ЗТЗ-Сервіс" є розробником

Керівних документів з транспортування, зберігання, монтажу і введенню в експлуатацію трансформаторів 110-750кВ

Технічних вимог до технологічного устаткування по обробці масла і ізоляції

Технології сушки ізоляції і захисту від зволоження

Процес

Повний цикл робіт

По кожному з трансформаторів зберігається і аналізується архівна та електронна документація. Крім того НІЦ "ЗТЗ-Сервіс" є власником архівної та електронної документації понад 2000 ремонтів потужних силових трансформаторів і реакторів вироблених з 1965р

Планування

Визначаємо ефективні методи, способи та ресурси потрібні для виконання сервісних завдань

Розробка

Готуємо конструкторську, технологічну та програмну документацію

Втілення

Виконуємо роботу із максимальною якістю та надійністю

Якість

Найвища якість на ринку

Основою діяльності НІЦ «ЗТЗ-Сервіс» є розвиток наукової і виробничої бази, розробка нових методик, технологій, постійний розвиток і вдосконалення.

Контроль якості

Вдосконалення

Надійність

Ми використовуємо cookies для корректної роботи сайта, покращення якості інформації, що надається, та аналітики. Використовуючи наш сайт Ви надаєте згоду з використання cookies.